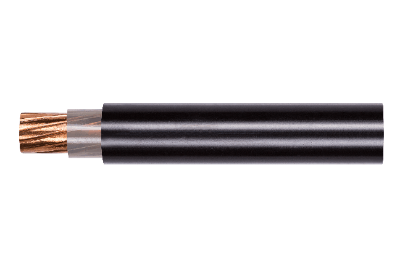

Polyethylene (PE) imagwiritsidwa ntchito kwambiri m'mafakitale.kutchinjiriza ndi kuphimba zingwe zamagetsi ndi zingwe zolumikiziranachifukwa cha mphamvu zake zabwino kwambiri zamakanika, kulimba, kukana kutentha, kutchinjiriza, komanso kukhazikika kwa mankhwala. Komabe, chifukwa cha mawonekedwe a PE yokha, kukana kwake kupsinjika kwa chilengedwe kumakhala kochepa. Vutoli limakhala lodziwika bwino kwambiri pamene PE imagwiritsidwa ntchito ngati chivundikiro chakunja cha zingwe zazikulu zotetezedwa.

1. Njira Yopangira Chidebe cha PE

Kusweka kwa chidebe cha PE kumachitika makamaka m'mikhalidwe iwiri:

a. Kusweka kwa Nkhawa pa Chilengedwe: Izi zikutanthauza vuto lomwe chigoba chimasweka kuchokera pamwamba chifukwa cha kupsinjika kapena kukhudzidwa ndi zinthu zachilengedwe pambuyo poyika chingwe ndikugwiritsa ntchito. Izi zimachitika makamaka chifukwa cha kupsinjika kwamkati mkati mwa chigoba komanso kuwonetsedwa kwa nthawi yayitali ndi madzi a polar. Kafukufuku wochuluka pakusintha kwa zinthu wathetsa vutoli.

b. Kusweka kwa Makeniketi: Izi zimachitika chifukwa cha kusowa kwa kapangidwe ka chingwe kapena njira zosayenerera zotulutsira chidebe, zomwe zimapangitsa kuti pakhale kupsinjika kwakukulu komanso kusweka komwe kumachitika chifukwa cha kusokonekera kwa chingwe panthawi yoyika chingwe. Mtundu uwu wa kusweka umaonekera kwambiri m'zidebe zakunja za zingwe zazikulu zotetezedwa ndi tepi yachitsulo.

2. Zomwe zimayambitsa kusweka kwa chidebe cha PE ndi njira zowongolera

2.1 Mphamvu ya ChingweTepi yachitsuloKapangidwe

Mu zingwe zokhala ndi mainchesi akuluakulu akunja, gawo lokhala ndi zida nthawi zambiri limapangidwa ndi zomangira zachitsulo zokhala ndi zigawo ziwiri. Kutengera ndi mainchesi akunja a chingwecho, makulidwe a tepi yachitsulo amasiyana (0.2mm, 0.5mm, ndi 0.8mm). Matepi achitsulo okhuthala amakhala olimba kwambiri komanso osalala, zomwe zimapangitsa kuti pakhale mtunda waukulu pakati pa zigawo zapamwamba ndi zapansi. Panthawi yotulutsa, izi zimapangitsa kusiyana kwakukulu kwa makulidwe a sheath pakati pa zigawo zapamwamba ndi zapansi za pamwamba pa gawo lokhala ndi zida. Malo ocheperako a sheath m'mphepete mwa tepi yachitsulo yakunja amakhala ndi nkhawa yayikulu ndipo ndi malo oyamba kumene ming'alu imachitika mtsogolo.

Pofuna kuchepetsa kukhudzidwa kwa tepi yachitsulo yotetezedwa pa chivundikiro chakunja, gawo lotetezera la makulidwe enaake limakulungidwa kapena kutulutsidwa pakati pa tepi yachitsulo ndi chivundikiro cha PE. Gawo lotetezerali liyenera kukhala lolimba mofanana, lopanda makwinya kapena kutuluka. Kuwonjezera gawo lotetezera kumathandizira kusalala pakati pa zigawo ziwiri za tepi yachitsulo, kumatsimikizira makulidwe ofanana a chivundikiro cha PE, ndipo, kuphatikiza ndi kupindika kwa chivundikiro cha PE, kumachepetsa kupsinjika kwamkati.

ONEWORLD imapatsa ogwiritsa ntchito makulidwe osiyanasiyana atepi yachitsulo yolimba yokhala ndi zida zomenyerakukwaniritsa zosowa zosiyanasiyana.

2.2 Zotsatira za Njira Yopangira Zingwe

Mavuto akuluakulu okhudza njira yotulutsira zingwe zazikulu zakunja zokhala ndi mainchesi awiri ndi kuziziritsa kosakwanira, kukonzekera bwino kwa nkhungu, komanso kuchuluka kwa kutambasula kwa zingwe, zomwe zimapangitsa kuti mkati mwake mukhale ndi kupsinjika kwakukulu. Zingwe zazikulu, chifukwa cha zingwe zake zokhuthala komanso zazikulu, nthawi zambiri zimakhala ndi zoletsa kutalika ndi kuchuluka kwa zingwe zamadzi pamizere yopangira zingwe. Kuziziritsa kuchokera madigiri opitilira 200 Celsius panthawi yotulutsa zingwe mpaka kutentha kwa chipinda kumabweretsa zovuta. Kuziziritsa kosakwanira kumabweretsa chikwama chofewa pafupi ndi gawo la zingwe, zomwe zimapangitsa kuti chikwamacho chizikwirire pamwamba pa chingwecho chikakulungidwa, zomwe pamapeto pake zimapangitsa kuti ming'alu ndi kusweka panthawi yoyika zingwe chifukwa cha mphamvu zakunja. Kuphatikiza apo, kuziziritsa kosakwanira kumathandizira kuwonjezeka kwa mphamvu zamkati pambuyo pozungulira, zomwe zimawonjezera chiopsezo cha kusweka kwa chikwama pansi pa mphamvu zazikulu zakunja. Kuti muwonetsetse kuti kuziziritsa kokwanira, kuwonjezera kutalika kapena kuchuluka kwa zingwe zamadzi kumalimbikitsidwa. Kuchepetsa liwiro la extrusion pamene mukusunga pulasitiki yoyenera ya chikwama ndikulola nthawi yokwanira yoziziritsira panthawi yozungulira ndikofunikira. Kuphatikiza apo, kuganizira polyethylene ngati crystalline polymer, njira yoziziritsira yochepetsera kutentha, kuyambira 70-75°C mpaka 50-55°C, ndipo potsiriza mpaka kutentha kwa chipinda, kumathandiza kuchepetsa kupsinjika kwamkati panthawi yozizira.

2.3 Mphamvu ya Coiling Radius pa Cable Coiling

Pa nthawi yozungulira chingwe, opanga amatsatira miyezo yamakampani posankha ma reel oyenera otumizira. Komabe, kuyika ma reel ataliatali a zingwe zazikulu zakunja kwa diameter kumabweretsa zovuta posankha ma reel oyenera. Kuti akwaniritse kutalika komwe kwatchulidwa, opanga ena amachepetsa mainchesi a ma reel barrel, zomwe zimapangitsa kuti chingwecho chisapindike mokwanira. Kupindika kwambiri kumabweretsa kusuntha kwa zigawo za zida, zomwe zimapangitsa kuti chipolopolocho chikhale ndi mphamvu zambiri zodula. Pazochitika zoopsa, ma burrs a chitsulo chotetezedwa amatha kuboola gawo lothandizira, kulowa mwachindunji mu chipolopolo ndikuyambitsa ming'alu kapena ming'alu m'mphepete mwa chingwe chachitsulo. Pakuyika chingwe, mphamvu zopindika ndi kukoka za mbali zimapangitsa kuti chipolopolocho chisweke m'ming'alu iyi, makamaka zingwe zomwe zili pafupi ndi zigawo zamkati za chipolopolocho, zomwe zimapangitsa kuti zikhale zosavuta kusweka.

2.4 Zotsatira za Ntchito Yomanga ndi Kukhazikitsa Malo Ogwirira Ntchito

Kuti muyike chingwe mofanana, tikukulangizani kuchepetsa liwiro la chingwe, kupewa kupanikizika kwambiri m'mbali, kupindika, kukoka mphamvu, ndi kugundana pamwamba, ndikuonetsetsa kuti malo omanga ndi abwino. Ndikwabwino, musanayike chingwe, lolani chingwecho chipumule pa 50-60°C kuti mutulutse mphamvu mkati mwa chingwecho. Pewani kuwonetsa zingwe nthawi yayitali ku dzuwa, chifukwa kutentha kosiyana mbali zosiyanasiyana za chingwe kungayambitse kupsinjika, zomwe zimawonjezera chiopsezo cha kusweka kwa chikwama panthawi yoyika chingwecho.

Nthawi yotumizira: Disembala 18-2023